Designing for Speed: Practices by Oakter in White Label Manufacturing That Ensures Both Speed and Quality

The demand to create and introduce new products in the market has reached unprecedented levels in the current dynamic business landscape.

One approach that has gained significant popularity in recent years is white label manufacturing, which allows businesses to outsource the production of their products to specialised third-party manufacturers.

However, it is essential to balance speed and quality in product development to succeed in this highly competitive market. Oakter understands the importance of this balance and excels in providing efficient solutions.

In this article, we will explore Oakter’s practices in white label manufacturing that ensure both speed and quality in product development.

What is White Label Manufacturing?

White label manufacturing is a business model where a company outsources the production of goods to a third-party manufacturer who then supplies the products to be sold under the company’s own branding or label.

In this arrangement, the manufacturer remains anonymous, and the focus is on the brand owner’s marketing and distribution efforts.

The concept of white label manufacturing allows businesses to leverage the expertise and resources of specialised manufacturers without investing in their own production facilities.

The manufacturer produces the goods according to the brand owner’s specifications, ensuring the products meet the desired quality standards.

Importance of White Label Manufacturing in the Industry

The importance of white label manufacturing in the industry stems from the current market trends and consumer demands that businesses face.

Today’s consumers expect a wide range of high-quality products to choose from, and they often seek unique offerings tailored to their preferences. White label manufacturing plays a significant role in meeting these market demands effectively.

White label manufacturing allows companies to quickly respond to market trends and consumer demands by leveraging the expertise of specialised manufacturers.

Advantages of White Label Manufacturing

White label manufacturing offers several advantages that make it an attractive choice for businesses looking to outsource their product development and production. Let’s explore these advantages in detail:

1. Cost-effective production and reduced time-to-market

White label manufacturing offers cost-effective production and faster time-to-market. By partnering with a specialised manufacturer, companies avoid setting up their own facilities and equipment, reducing upfront costs, overhead expenses, and production risks.

White label manufacturing also streamlines the production process, enabling businesses to quickly bring products to market and capitalise on opportunities without the complexities of in-house production.

2. Increased brand exposure and market reach

White label manufacturing expands brand exposure and market reach. By leveraging a trusted manufacturing partner, companies can focus on branding, marketing, and customer engagement.

They can introduce a broader range of products under their own brand, catering to diverse customer needs. This enhances brand visibility and allows businesses to tap into new market segments and customer demographics.

3. Customisation and branding opportunities

White label manufacturing enables product customisation and branding opportunities. Businesses can work closely with the manufacturing partner to define product specifications, meet specific requirements and align with brand image.

It differentiates companies from competitors, serving niche markets or specialised customer segments. By adding branding elements, businesses create a distinct product identity and connect with their target audience.

The Need for Speed in Product Development

In today’s rapidly changing market, businesses must stay ahead of the competition by launching new products quickly. Launching products faster than competitors can give a business a significant advantage.

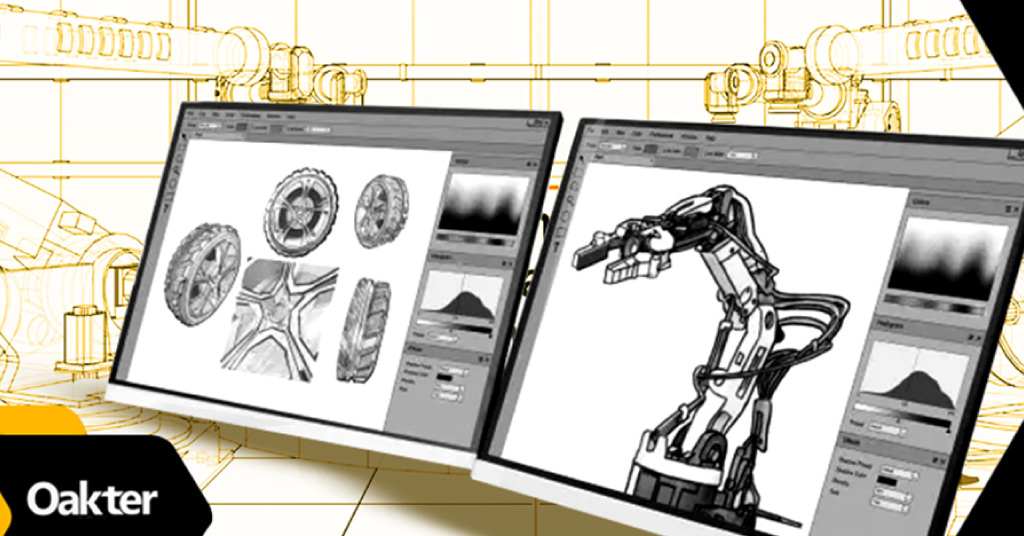

This is where Oakter’s approach to streamlining hardware design comes in handy. Oakter’s experienced team of engineers uses a combination of design thinking, agile methodologies, and cutting-edge technology to speed up the production process.

Oakter’s agile manufacturing processes also ensure a quick turnaround time. This approach makes Oakter more responsive to market trends and changing consumer demands.

Why is Quality Indispensable in Product Development?

While speed is crucial in product development, quality cannot be overlooked. A poor-quality product can damage a brand’s reputation and lead to financial losses. This is why Oakter places a high emphasis on rigorous quality assurance measures.

Oakter’s quality assurance process includes several stages of testing, including design validation, design verification, and production validation. The company also conducts extensive user testing to ensure its products meet the target market’s needs.

Balancing Speed and Quality: Improving Enterprise Data Governance

White label manufacturing involves the challenge of striking a balance between speed and quality. While businesses strive to bring products to market quickly, they must ensure that the quality of the products is not compromised. This delicate balance requires effective enterprise data governance.

Enterprise data governance is crucial in balancing speed and quality in white label manufacturing. It involves managing, protecting, and utilising data throughout the product development process. By establishing robust data governance practices, companies can make informed decisions, mitigate risks, and maintain the desired level of quality.

Oakter recognises the importance of enterprise data governance in its white label manufacturing operations. They have implemented stringent measures to improve data governance and achieve better results.

For instance, Oakter maintains a centralised data repository that ensures data accuracy, integrity, and accessibility for all stakeholders involved in the manufacturing process. This enables real-time collaboration and decision-making, facilitating faster product development cycles.

Achieving the Right Balance between Speed and Quality in White Label Manufacturing with Oakter

The importance of balancing speed and quality in white label manufacturing cannot be overstated.

Achieving a delicate equilibrium between these two factors enables businesses to capitalise on market opportunities, outpace competitors, and uphold customer satisfaction and brand reputation.

By collaborating with a reputable white label manufacturing company such as Oakter, businesses gain access to a multitude of advantages.

Oakter’s proficiency in optimising hardware design, implementing agile manufacturing processes, and enforcing stringent quality assurance measures positions them as an esteemed partner for enterprises.

Don’t hesitate any longer. Take the first step and get in touch with us today!