Conflict of Interest Solutions: Embracing Original Design Manufacturers (ODMs) for Customized Products

In the world of product manufacturing, conflicts of interest can jeopardise the integrity of the manufacturing process and customer satisfaction.

It is vital to address these conflicts, especially in the case of customised products. In fact, a recent study revealed that 75% of consumers expect companies to address conflicts of interest when producing customised products.

To tackle this challenge, Original Design Manufacturers (ODMs) emerge as a viable solution. ODMs specialise in providing design and manufacturing solutions for customised products, minimising conflict of interest and ensuring a smooth production ecosystem.

In this article, we will explore how embracing ODMs can effectively mitigate conflicts of interest in manufacturing. So let’s dive in!

Uncovering Conflicts of Interest in Product Manufacturing: A Comprehensive Analysis

Conflict of interest refers to situations where individuals or entities have competing interests that may compromise their objectivity or decision-making.

In product manufacturing, conflicts of interest can arise when a company or its employees have personal or financial interests that conflict with their duty to provide quality products.

For example, a manufacturer using substandard materials to cut costs or a supplier favouring certain clients over others due to personal connections.

Additionally, conflicts of interest can have detrimental effects on product quality and customer satisfaction. When manufacturers prioritise their interests over delivering high-quality products, it can compromise safety, durability, or performance.

This can result in dissatisfied customers, negative reviews, and a damaged brand reputation. Customers expect products that meet their needs and provide value, and conflicts of interest hinder the ability to meet those expectations.

Exploring the Power of Original Design Manufacturers (ODMs) in Manufacturing

Original Design Manufacturers (ODMs) play a significant role in the manufacturing industry, particularly in the production of customised products.

ODMs provide comprehensive design and manufacturing solutions for companies that aim to bring unique, tailored products to market. Partnering with ODMs offers a range of advantages for manufacturers seeking to deliver customised products efficiently and effectively.

Here are some of the benefits of ODM partnerships:

1. In-depth Expertise in Product Design and Development

ODMs have skilled teams of designers and engineers who understand market trends and consumer preferences, ensuring customised products are visually appealing, functional, and aligned with market demands.

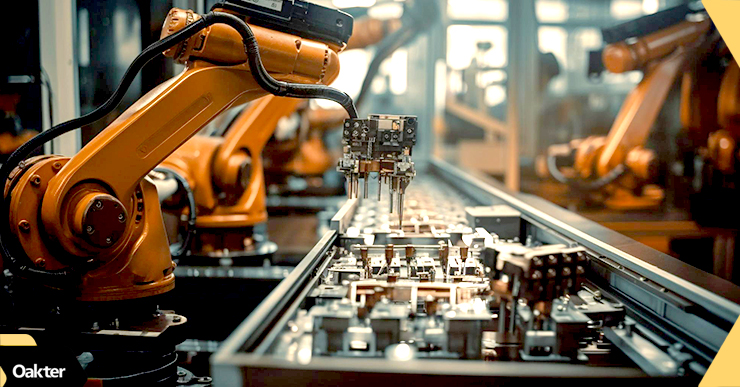

2. Access to Advanced Manufacturing Capabilities

ODMs possess state-of-the-art facilities and leverage cutting-edge technology and production processes, allowing manufacturers to access advanced manufacturing capabilities without significant investments.

3. Cost-effectiveness and Reduced Time-to-Market

Working with ODMs reduces costs by avoiding expenses for setting up and managing production lines. ODMs operate with economies of scale, ensuring cost-effective manufacturing solutions and faster production and delivery.

4. Flexibility in Meeting Specific Customer Requirements

ODMs offer flexibility in adapting their processes to meet unique design elements, features, or functionalities manufacturers request. This allows for tailored products that align with specific market segments or individual customer preferences.

Conflict of Interest Solutions: Embracing ODMs for Customised Products

When it comes to resolving conflicts of interest in the manufacturing of customised products, embracing Original Design Manufacturers (ODMs) offers effective solutions. Here are key ways ODMs can address conflicts of interest:

1. Increased Transparency and Accountability through Independent Manufacturing Partners

By partnering with independent ODMs, manufacturers can enhance transparency and accountability. ODMs operate as impartial entities, free from biases or vested interests that may compromise product quality. This transparency ensures a fair and ethical manufacturing process that prioritises customer satisfaction.

2. Mitigating Conflicts through Diversified Supply Chains

ODMs provide diversified supply chains, reducing dependencies on single suppliers. This mitigates conflicts of interest that may arise from favouritism or biased decision-making. By leveraging ODMs, manufacturers can ensure a competitive and unbiased manufacturing process, safeguarding the integrity of their customised products.

3. Leveraging ODMs for Product Innovation and Differentiation

ODMs bring a wealth of expertise and experience in product design and development. Collaborating with ODMs allows manufacturers to tap into their innovative capabilities, enabling them to create unique and differentiated customised products. This helps manufacturers stand out in the market and meet the evolving needs of their customers.

4. Enhancing Consumer Trust and Satisfaction with Customized Products

By embracing ODMs, manufacturers can enhance consumer trust and satisfaction. ODMs provide the necessary expertise, resources, and processes to deliver high-quality custom products that align with customer expectations. This commitment to quality and a customer-centric approach fosters trust and loyalty among consumers, strengthening the manufacturer’s brand reputation.

4 Best Practices for Effectively Embracing ODMs in Customisation

To embrace ODMs successfully, manufacturers should adopt best practices, including:

1. Conducting Thorough Due Diligence and Background Checks on Potential ODM Partners

Before entering into a partnership, manufacturers should thoroughly assess potential ODM partners. This includes verifying their financial stability, capabilities, quality control processes, and adherence to ethical and environmental standards.

2. Establishing Clear Contractual Agreements and Intellectual Property Protection Measures

Clear and comprehensive contractual agreements are crucial. Manufacturers should work with legal experts to define ownership rights, intellectual property protection, product specifications, quality standards, delivery schedules, and confidentiality clauses.

3. Maintaining Open and Transparent Communication Channels with ODMs

Effective communication is key to successful collaboration. Regular communication, including video conferences, progress updates, and project management tools, helps ensure that both parties are aligned, fostering trust and minimising misunderstandings.

4. Consistently Evaluating and Monitoring ODM Performance and Compliance

Ongoing evaluation and monitoring of the ODM’s performance and compliance are essential. Manufacturers should establish metrics, conduct regular audits, and promptly address performance or compliance issues. This ensures continuous improvement and accountability.

ODMs: The Key to Conflict Resolution & Customer Satisfaction in Manufacturing

Addressing conflicts of interest in manufacturing is paramount to upholding product quality and customer satisfaction. Embracing ODMs as a solution offers numerous benefits, including transparency, diversified supply chains, innovation, and consumer trust.

By following best practices, manufacturers can forge successful partnerships with ODMs, such as Oakter. Oakter offers comprehensive solutions, from design to manufacturing, and has a proven track record of shipping over 500,000 products per month.

By embracing ODMs, manufacturers can effectively mitigate conflicts of interest and deliver exceptional customised products that meet and exceed customer expectations.

Contact us today to explore how their expertise can transform your manufacturing process.