A Deep Dive Into the Future of EMS Manufacturing

Over the last two years, the dynamics of manufacturing have drastically evolved. The pandemic of 2020 completely disrupted the supply chains as we know them. Global shortages of electronic components vital in making a wide range of products impacted the manufacturing capabilities of companies across sectors.

Since then, several electronics companies have shifted toward Electronic Manufacturing Services (EMS) Manufacturing. Digital transformation has also pervaded almost every sector, pushing companies to innovate and bring superior, cutting-edge products. This blog delves deep into the concept of EMS manufacturing, its benefits in a tech-fuelled world, and what the future will look like.

What is EMS Manufacturing?

Until the pandemic hit, outsourcing manufacturing to cheaper destinations was all about cutting costs and increasing profitability. However, original equipment manufacturers (OEM) realised this model is no longer sustainable due to the unpredictability of globally connected supply chains.

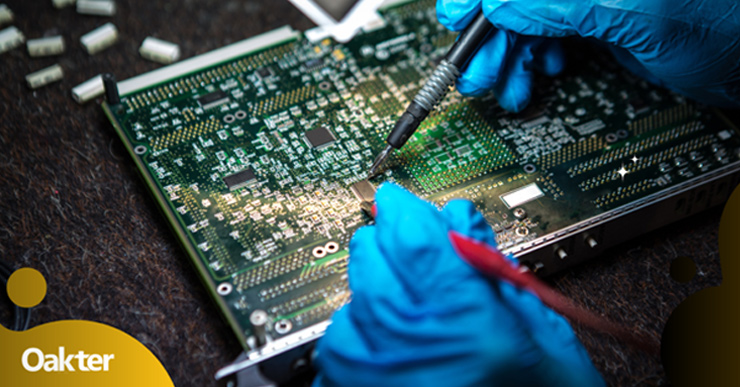

EMS manufacturing refers to a more evolved form of outsourcing products or electronic components manufacturing to a highly specialist contractor to produce niche, cutting-edge products. However, unlike traditional outsourcing models, this process is differentiated because it brings more to the table than merely cost considerations.

EMS manufacturing companies cover the full spectrum of services for Original Equipment Manufacturers (OEMs): from design and assembly to production of quality testing of electronic components or finished products. The outsourcing process may be either off-shore or on-shore, but there’s a high premium placed on the quality output of the contractor.

Future of EMS manufacturing

In 2021, the global EMS manufacturing services market was valued at $ 476.88 billion in 2021. The sector is expected to grow from $ 504.22 billion in 2022 to $ 797.94 billion by 2029 at a compound annual interest rate (CAGR) of 6.8 %. Several factors are accelerating the growth of this trend.

-

Demand for innovative products and services

Sectors such as health care, industrial applications, consumer electronics, and the automotive sectors are continuously innovating to produce digitally-connected products and systems.

For instance, technology such as the internet of things (IoT) is being used extensively in sectors such as consumer electronics. By leveraging EMS manufacturing, electronics companies can focus on their core strength which is to design and deliver innovative products to the market at scale and a desired speed.

-

Specialised knowledge in manufacturing

Contemporary manufacturing units demand superior and advanced functionalities to produce contemporary products. Innovation is as much a requirement of EMS manufacturing as it is a requirement of electronics companies. Companies can no longer continue to outsource their manufacturing requirements to generic manufacturing units.

-

Higher value, lower costs

EMS manufacturing specialists function as partners to electronics companies. They developed a specialised understanding of their client’s needs and can offer cutting-edge manufacturing solutions. It comes with a definitive cost advantage as compared to electronics companies that undertake manufacturing processes in-house.

-

Take products to market faster

Both established businesses and newer players are continuously looking to take new products to market faster. EMS manufacturing companies provide the muscle and speed required to expedite the launch of new products without compromising quality.

New players may also find manufacturing setup costs to be exorbitant. EMS manufacturing partners fulfil a niche function for companies operating on the cusp of innovation and empower them to meet their targets and vision.

Key industries leveraging EMS manufacturing

Many industries are partnering with EMS manufacturing specialists to fulfil their manufacturing needs as follows:

-

Smart consumer electronics

With the rise in disposable incomes, more consumers can afford a range of consumer electronics, from smartphones and air conditioners to laptops, ovens, and refrigerators. With technological advances, these devices are becoming more brilliant with technology such as IoT, which helps conserve energy and increase efficiency. EMS manufacturing is fully capable of producing superior consumer electronics of the future.

-

Health care

Today, digital transformation has accelerated the rate at which the healthcare ecosystem is adopting smart medical and diagnostic devices connected to a larger ecosystem via the cloud. EMS manufacturing specialists have the expertise to produce innovative products and services for the industry at scale.

-

Electronic components

A wide range of industries produces equipment that requires access to electronic components such as semiconductors and connectors. These need to be produced at scale and to spec, with perfection, and EMS manufacturing specialists are best poised to do so over generic manufacturing units.

-

Automotive

This is another sector that has undergone immense transformation due to the adoption of digital technologies. Today’s vehicles are fitted with advanced communication, data, and location capabilities. OEMs may outsource components or fully-finished products based upon their needs from EMS manufacturing specialists.

-

Defence and Aerospace

With nations investing in building up their national security armour due to the rising threat of global nuclear warfare, modern defence equipment has undergone a massive transformation. The new combat and security equipment has more advanced capabilities requiring specialist manufacturing interventions.

-

Industrial automation

The industrial world is always looking to save costs by automating various processes. Companies are investing in upgrading their production equipment by leveraging robotics and automation technology’s high productivity and accuracy potential. EMS manufacturing specialists can produce superior machinery to fuel this transformation.

-

Sustainable energy

Aligned with sustainable development models, energy providers are shifting towards more sustainable energy sources; for instance, harnessing the potential of solar and wind energy to fuel the energy grids. EMS manufacturing specialists have the capabilities to produce the innovative components and finished equipment required to build these ecosystems.

In Conclusion

By leveraging EMS manufacturing services, companies across several sectors can benefit from producing high-quality products and components at lower costs and higher efficiency and accuracy. These benefits directly impact companies’ sustainability, reputation, and profitability in unpredictable markets.

Oakter’s EMS Manufacturing services facilitate the complete cycle from concept to full-scale manufacturing for OEMs operating on the cusp of innovation. The spectrum of products delivered ranges from connected electronics development and full stack IOT software development to battery technology. With its capabilities at scale, Oakter can bring efficiency and quality to your manufacturing outcomes.

Reach out to us to know more!