Flexibility vs Focus: Comparing EMS and ODM Manufacturing

- https://slotjitu.com/

- https://linkslotjitu.com/

- jual303

- jual 303

- slot

- https://heylink.me/jual303/

- https://www.slotjitu.id/

- https://slot-gacor.id

- https://slot-gacor-2026.com

- https://adslotgacor.com/

- https://slotgacor77.id/

- https://slotjitu.net/

- https://bento.me/kawasan303/

- https://www.slotdepo10k.id/

- https://www.slotraffiahmad77.com/

- https://togelsgp2023.com/

- https://www.slotraffiahmad88.com/

- https://www.slotraffiahmad.net/

- https://www.slotraffiahmad.org/

- https://slotgacor-maxwin.com/

- https://www.nausenaadventures.com/

- https://www.kawasan303.org/

- https://slotscatterhitamgacor.com/

- https://superscatterhitam.com/

- https://www.slotraffiahmad.id/

- https://suleslotgacor.com/

- https://www.kawasan303.com/

- https://pgslottop.id/

- https://kawasan138.com/

- https://slotsuleofficial.com/

- https://slot-raffi-ahmad.com/

- https://scatterhitamgacor.com/

- https://linkslotgacor.id/

- https://sundulbola.com/

- https://ucosigtau.com/

- https://www.ia-itb.com/

The electronics manufacturing sector comprises a network of enterprises offering manufacturing services for various product categories and business sizes- ranging from start-ups to small businesses to well-established multinational corporations.

However, two key electronics manufacturing approaches have emerged as dominant processes: EMS (Electronic Manufacturing Services) and ODM manufacturing (Original Design Manufacturing). However, businesses frequently struggle to decide which to use for their particular product.

This blog article explores the manufacturing worlds of OEM and EMS and can help you make a knowledgeable decision while choosing a service provider based on the manufacturer’s specialisation and your product.

So, let’s understand these two models of marketing.

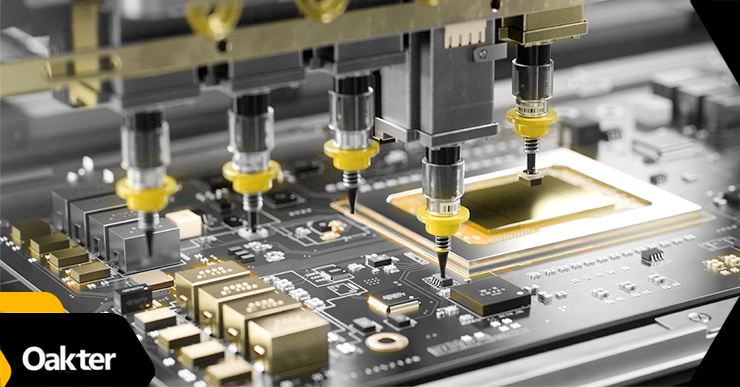

EMS Manufacturing: An Overview

Electronic Manufacturing Services, or EMS, is a manufacturing model in which you can contract with a third-party manufacturer to produce your electronic goods or components. Therefore, an EMS company is essentially a contract manufacturer.

Electronic component and assembly design, manufacture, testing, shipping, and repair are just a few of the many services that an EMS may provide. In addition, they could work on software design projects, develop new products, or provide additional value-added services.

When to Opt for EMS Manufacturing?

Here are some scenarios that call for an EMS manufacturing approach:

1. When adaptability and flexibility matter

EMS production’s high degree of flexibility is one of its main advantages. It enables you to adjust your production levels in response to changes in your consumer demand. This flexibility is also invaluable if you have fluctuating production requirements.

2. When your product’s design is intricate

EMS manufacturing could be preferable for you if you need to produce intricately designed items that require close supervision and coordination since it allows for detailed production process oversight.

3. If you are catering to specialised markets

EMS production makes customisation and experimentation possible. It is a great option, particularly if you are involved in invention, prototyping, or providing highly specialised products to niche markets.

4. When cost-cutting is required

You can save money on the high overhead expenses of in-house production by outsourcing manufacturing to EMS providers. This includes the costs of maintaining industrial facilities, acquiring and training employees, and purchasing specialised equipment.

5. When time is of the essence

EMS companies are well-equipped to handle the manufacturing process effectively. This can result in a shorter time-to-market for new products, which is critical in today’s fast-paced business environment.

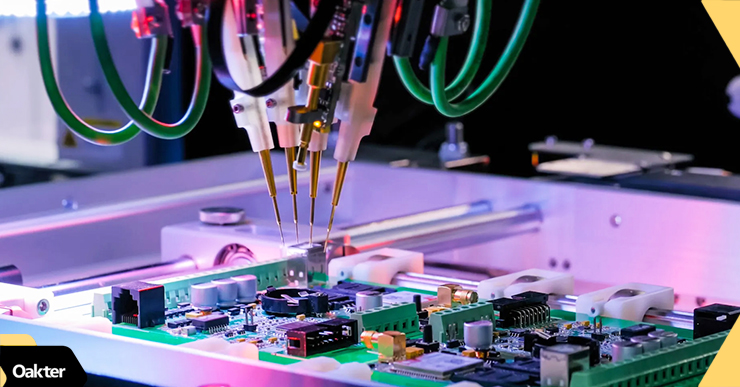

ODM Manufacturing: An Outline

ODM, or Original Design Manufacture, is a manufacturing model in which another company develops and manufactures products for you to white label and sell as your own.

ODMs are often more involved in the product’s design and development. They typically have a catalogue of current designs and technology that may be customised to match your exact demands. They often specialise in a limited number of product types.

An ODM normally owns the product’s intellectual property- they develop their own specialised intellectual property (IP) for specific markets.

As a result, ODM manufacturing refers to a service that includes design and manufacture.

When to Choose ODM Manufacturing?

Here are some ideal scenarios that fit with ODM manufacturing:

1. When you want to focus on your core competencies

One of the primary advantages of ODM manufacturing is that it allows you to focus on market research, business strategy, brand development, marketing, and distribution while your contracted ODM manufacturer handles the complete production process.

As a result, if you want to streamline and simplify your operations while focusing on core strengths, you can use ODM manufacturing to manage production, making it a win-win situation for both sides.

2. To save money

ODM manufacturing frequently works on a large scale, which results in cheaper costs that may be passed on to you, their customer. These savings might benefit your company, especially if you aim to maximise profit margins.

Furthermore, outsourcing design and manufacturing processes to an ODM reduces costs since they have access to larger economies of scale and specialised design and manufacturing know-how.

3. When time is money

ODM manufacturing is also beneficial when you want to introduce new products to the market quickly. This is because you do not need to invest in design and manufacturing, nor do you need time, effort, or a large budget for tooling or building production facilities. All you have to focus on is product customisation and marketing.

Businesses with fewer resources, particularly small enterprises and hardware startups, can benefit greatly from this model.

4. To reduce risk

ODM manufacturers are often specialists in their industry, which reduces the likelihood of production-related complications. Hence, this can be a boon if you search for a trouble-free production experience.

5. To produce with less hassle

If you can use pre-existing product designs or if the available designs meet your requirements, ODM manufacturing can be a simple and hassle-free option.

This does not, however, imply that you must stick with old designs. ODMs provide enterprises with a degree of flexibility.

Therefore, you can work with your partner to customise the manufacturing process, from employing specific materials and components to incorporating unique design features or capabilities.

Which One Is Better- Flexibility or Focus?

The answer depends on your business objectives, priorities, specific needs, product goals, level of control/customisation, and priorities.

- EMS companies can offer you a wide range of manufacturing services and flexibility, making them suitable if you already have a well-designed product and need assistance with manufacturing.

- On the other hand, ODM manufacturing specialises in helping with product design and offers a structured approach to production. They are ideal if you require assistance from concept to production.

EMS and ODMs have become integral to the electronics manufacturing industry worldwide. These models allow you to use specialised skills and experience to produce quality products economically and efficiently.

Yes, there are numerous advantages to outsourcing. However, there are also potential drawbacks.

So, selecting an EMS /ODM manufacturing partner must be done with rigorous care, considering credentials, quality standards, and comprehensive contractual agreements for optimal results.

Last but not least, when considering whether to use an EMS or work with an ODM, it is also essential to consider other factors like cost, lead time, and production capabilities when coming to this decision.

Final Note

Choosing between EMS and ODM manufacturing hinges on your business goals, product complexity, and market needs, balancing flexibility and focus to optimise production strategy and cost efficiency.

Oakter is an advanced Indian ODM. We are competent manufacturing partners with outstanding credentials and experience producing various electronic products for reputed companies.

To find out how to partner with us, get in touch.