Best Practices for Companies Looking for Contract Manufacturing to Optimise Workflows

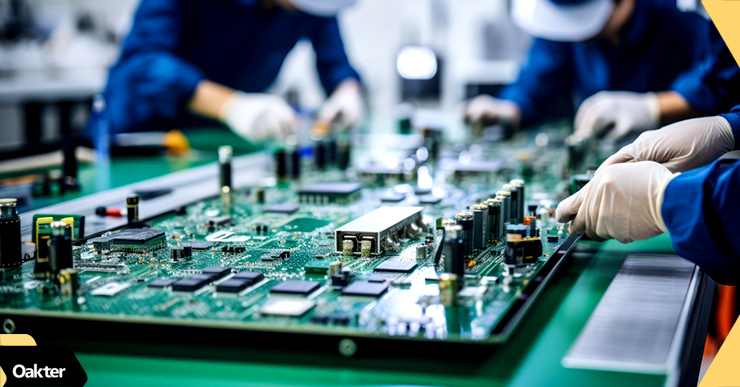

Contract manufacturing refers to hiring an external manufacturer to produce products, parts, or components on behalf of another company.

The global contract manufacturing market has experienced significant growth recently, valued at $246.51 billion in 2022 and projected to reach $512.74 billion by 2030 at a 9.58% CAGR.

Companies looking for contract manufacturing can benefit greatly from this manufacturing approach, as they can focus resources on core competencies while leveraging the specialisation and efficiencies of manufacturing partners.

However, in order for companies to fully optimise workflows, it is critical to implement certain best practices when selecting and working with contract manufacturers.

This article outlines key strategies companies looking for contract manufacturing should employ to ensure smooth, efficient, and mutually beneficial partnerships.

Companies Looking for Contract Manufacturing: 8 Best Practices

Here are some of the most common practices to consider for companies looking for contract manufacturing:

1. In-Depth Market Research

Conducting meticulous market research by comparing contract manufacturers across important evaluation criteria is invaluable for finding the optimal strategic partner. Key factors for comparison include:

- Specific manufacturing capabilities

- Quality systems and accreditations

- Client portfolios

- Production plant locations

- Reputations for service and innovation

Speak with trade groups and industry networks, search relevant directories, and request referrals to aid in the process. Develop a list of top considerations in a potential partner, then extensively research all options across these criteria using available public information to narrow down to a select few contenders.

2. Creating a Highly Detailed Request for Proposal

A comprehensive Request for Proposal (RFP) leaves no ambiguity around precise requirements while allowing for an apples-to-apples evaluation of proposals. Frame details around the following:

- Production Volumes Needed: Details on the quantity and frequency of production.

- Product Specifications: Inclusions of technical drawings, prototypes, and 3D models.

- Quality Needs: Guided by zero defect process mapping standards.

- Custodial and Legal Elements: Legal requirements and custodial responsibilities.

- Location Priorities: Preferences or requirements for production or distribution locations.

- SLAs and KPIs: Service Level Agreements and Key Performance Indicators.

- Preferred Pricing Models: Desired pricing structures and models.

- Logistics Plans: Complete plans for transportation, storage, and distribution.

Outline required communication structures, inspection and audit processes, transparency needs, and other operational prerequisites while delineating current and projected supply chain solution capabilities.

3. Take Advantage of Government Incentives

Conduct exhaustive research on government and regional economic development incentives available.

For example, the Indian government has launched the Production Linked Incentive (PLI) Scheme 2.0 for IT Hardware to boost domestic manufacturing and exports of IT hardware products such as laptops, tablets, all-in-one PCs, servers, and ultra-small form factor devices.

The scheme offers an average incentive of around 5% on net incremental sales (over a base year) of goods manufactured in India for a period of six years. To be eligible for the scheme, companies must invest a minimum amount in India and achieve a minimum threshold of cumulative incremental sales of manufactured goods.

The recently announced expansion of India’s PLI scheme through PLI 2.0 for the IT hardware manufacturing sector plans over $5B USD in incentives over the next 4 years, which certified contract manufacturers and their clients would do well to leverage during this opportune business climate.

4. Assessing for Operational Excellence

Conduct multifaceted assessments by examining ISO or equivalent certifications for integrated quality management processes, Six Sigma and Lean Manufacturing protocols, critical safety stock monitoring, contingency planning, capabilities around rapid high-mix low-volume production, and technology usage for advanced planning like automation, IoT, analytics, and AI.

Look for data-driven decision-making capabilities and real-time production tracking of WIP inventory for adjustments as needed. Require evidence of reliability capabilities across power and production needs.

You may also statistically evaluate first-pass yield rates and quality performance across lengthy durations to minimise risks of failures or delays which derail client-side supply chains. Assess flexibility factors on rapid shift capabilities if unexpected spikes in certain product demand arise.

5. Strategic Site Visits

Simply put, seeing is believing. Make the time to personally visit one or more prospective contract manufacturing facilities to lend invaluable first-hand insights around operational aspects like workplace organisation, plant layout, and employee competency levels in executing required production processes.

Meet key engineers and managers responsible for project execution. Thoroughly assess cultural elements conducive to positive collaborative workplaces and ongoing learning, which lend themselves to partner-like engagements.

6. Legally Vetting Terms for Risk Mitigation

Enlist a qualified legal team specialising in contract law to fully assess proposed terms to safeguard intellectual property while shielding companies from undue liability risks. Ensure highly specific language around defect and failure warranty clauses.

Create clarity around dispute resolution pathways should challenges emerge. Establish projected production agreement durations while allowing opportunities for good faith renegotiation of terms as business climates evolve.

With a legally sound formal agreement in place for the appropriate protection of client interests, companies can focus on actualising optimised manufacturing methodologies, output quality, and collaborative engagements facilitating high-value additive production.

7. Clearly Define Product Specifications and Requirements

Provide extraordinarily comprehensive documentation around all facets of the product, components, regulatory compliance needs, quality testing protocols, and production environmental requirements.

This includes highly detailed technical drawings and 3D models indicating material specifications, surface finish requirements, tolerance analysis, and dimensional accuracy verification needs. Supply complete bill of materials incorporating approved vendor lists and analytical test record requirements for raw material validation.

8. Maintain Transparency and Frequent Communication

Make transparency core to the relationship, with both client and contract manufacturer openly sharing policies, strategic objectives, current capabilities and limitations, regulation changes with upstream or downstream impact, and continuous improvement goals.

Establish success metrics and key performance indicators (KPIs) for regular production reviews on meeting mutually agreed-upon targets. By assuming positive intent in all transparency discussions, both parties can strengthen their commitment to shared goals.

Additionally, schedule multi-channel forums like periodic strategy meetings between executive leadership and online portals for seamless day-to-day collaboration between production floor management.

Oakter: Your Path to Enhanced Efficiency in Manufacturing

Strategic contract manufacturing is a linchpin for businesses seeking efficient workflows. Companies can forge successful partnerships by implementing these best practices, ensuring quality, efficiency, and competitive advantage. Embrace the transformative power of contract manufacturing today.

At Oakter, we stand as a beacon of reliability and excellence in contract manufacturing. As a trusted contract manufacturer, we prioritise efficiency, quality, and innovation in every project. Take the next step toward optimising your workflow and enhancing your business outcomes by choosing us as your partner in success.

Contact us today to explore how our expertise can drive your business forward!