Evolution and Trends in Electronic Manufacturing Services

The electronic manufacturing services (EMS) market has been riding a wave of unstoppable change. The reliance on electronic devices has intensified in the last few years, fuelling a steady growth in the EMS sector.

The market was clocking in at an impressive US$ 525,271 million in 2022. And the 2033 projections suggest a sizzling US$ 859,959 million valuation!

Only a year prior, in 2022, the global electronic manufacturing market stood at US$ 525,271.0 million, driven primarily by rising consumer electronics sales. The growing user appetite for electronics is leading the charge and contributing to the key developments in the industry.

In this blog, we’ll touch on the bottom of these transformations in the electronic manufacturing services market and the key factors driving them.

Top 7 Electronic Manufacturing Services Industry Trends to Look Out for in 2023

Rising demand for electronics manufacturing faces supply unpredictability. Enhanced digital tools and innovative approaches are essential to navigate these challenges. Here’s a list of trends that are shaping the industry’s future:

1. Smart Devices Are on the Rise

In 2023 “smart” devices have become a necessity. For instance, with connected systems constantly feeding data during production, providers can oversee the intricate manufacturing processes more effectively.

This means they can spot problems quickly and fix them. It eventually sped up production. This also means that there are less chances of making mistakes.

However, sifting through vast data volumes efficiently poses significant obstacles. To address this, many electronic manufacturing services companies are investing in specialised software and training their workforce. By acting on relevant data, they can make more informed decisions.

2. Increase in use of AR and VR

Virtual Reality (VR) and Augmented Reality (AR) have become game-changers in the electronics manufacturing services industry. One popular example is how VR combines with computer-aided design to let designers see products in a virtual space. This helps them make changes quickly and more accurately than before.

Similarly, AR is proving invaluable during inspections. Workers can use AR to spot and correct mistakes in designs before they go into full-blown production. This not only speeds up the whole process but also saves money by cutting down on errors.

3. The Push for Eco-friendly Electronics

There’s a huge pressure on companies to make electronics more eco-friendly. People worldwide are becoming more environmentally conscious. And they’re looking to manufacturers to step up.

For example: With electronic devices shrinking in size but growing in complexity, less can be recycled or reused. However, this shift towards “greener” devices isn’t without challenges.

Tightening government regulations are pushing manufacturers to:

- Use fewer pollutants

- Opt for renewable resources

- And boost recycling

While this might mean higher initial costs, there are multiple long-term benefits like reducing energy consumption, a better image among eco-conscious consumers, etc.

4. Staying a Step Ahead with Predictive Maintenance

Electronic manufacturing services, like any industry, face equipment breakdowns. But what if businesses could anticipate these problems and prevent them?

Enter the strategy of Predictive Maintenance. It helps businesses figure out the best times to service their equipment by using data from condition-monitoring sensors.

For instance, by combining this with IoT technology, the health of equipment is watched non-stop. This means potential breakdowns are spotted and stopped before they happen. So, instead of reacting to a problem, businesses can act before it even starts, saving both time and money. This approach shifts from just fixing things to predicting and preventing issues.

5. The Big Data Revolution in Electronics Manufacturing

Enterprise companies aren’t the only ones using big data now. There was a time when it used to be too expensive for middle and small businesses. But with new tech like IoT, even SMEs can use big data.

For instance, by analysing big data, EMS manufacturers can cut down on wastage. It could significantly help them boost their profit margins. Big data helps them see patterns and trends they might’ve missed otherwise.

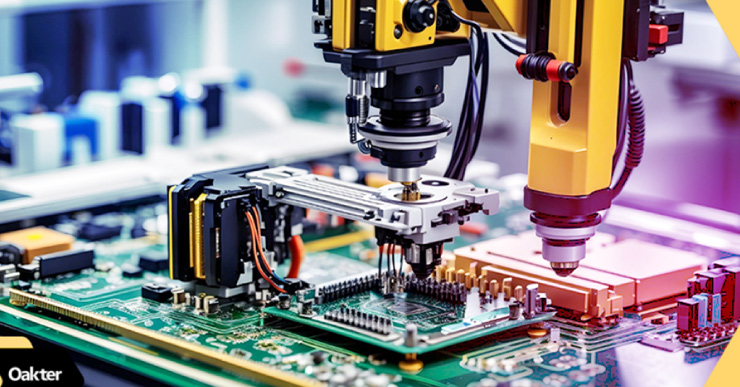

6. Robotics Revolution in Electronics Manufacturing

While cars once drove the rise of industrial robots, now it’s electronics manufacturing taking the lead. Robots have become a vital part of the equation as they let manufacturers boost efficiency.

These robots help manufacturers make microdevices and bring production closer to home. For example, with the aid of robots, companies can now achieve the intricate design and miniaturisation essential for today’s electronic devices.

7. Embedded systems are at the Centre of Modern EMS

The design and manufacturing sectors are evolving rapidly, striving to:

- Enhance performance

- Bolster security

- And ensure seamless connectivity

Take, for instance, electronics manufacturing facilities. They can grant heightened control over machinery, allowing for precise operations and real-time monitoring.

8. Evolution of Miniaturised Electronics

Miniaturisation has opened doors for electronics to make a mark in sectors like healthcare and automotive. In the past, the challenge was handling it practically and aspects like display and battery life.

But today, the focus has changed.

Now, it’s all about making small devices that work fast, don’t break easily, and can do a lot. It’s not just about making things smaller. It’s about cramming more features into every tiny chip. Innovations like nanonet sensors and forksheet FET are perfect examples, showcasing the boundless possibilities of compact electronic components.

Adapting to Change

The rapid pace of advancements in the electronics manufacturing domain teaches us one thing: trends can change overnight. Today’s groundbreaking innovation could be tomorrow’s norm.

While it’s vital to be aware of these shifting trends, partnering with a robust electronic manufacturing services provider like Oakter ensures that businesses can consistently produce quality electronic products efficiently and cost-effectively. Their services range from conceptualisation to large-scale manufacturing.

Ready with a product idea? Oakter can be of help!

Shipping 500k+ products each month, we are an advanced ODM based in India specialising in IoT, Consumer Electronics, EV Charge Points, PoS Soundboxes and more.

Reach out to us today and embark on a journey of innovation and excellence.