Key Insights from the Race to Develop Solid-State Batteries in EV Charging Manufacturing

Electric vehicles (EVs) are gaining immense popularity, with over 2.3 million sold in just the first quarter of 2023 – a 25% increase from the previous year.

As the market grows exponentially, manufacturers are racing to enhance EV technology, especially batteries.

By 2030, next-generation solid-state batteries are expected to power the electric vehicle market at a 5% rate.

These innovative batteries could revolutionise EV charging infrastructure with their higher energy density, faster charging capabilities, and improved safety. EV charging manufacturing companies have taken notice and are strategically positioned to leverage these advantages.

What are Solid-State Batteries?

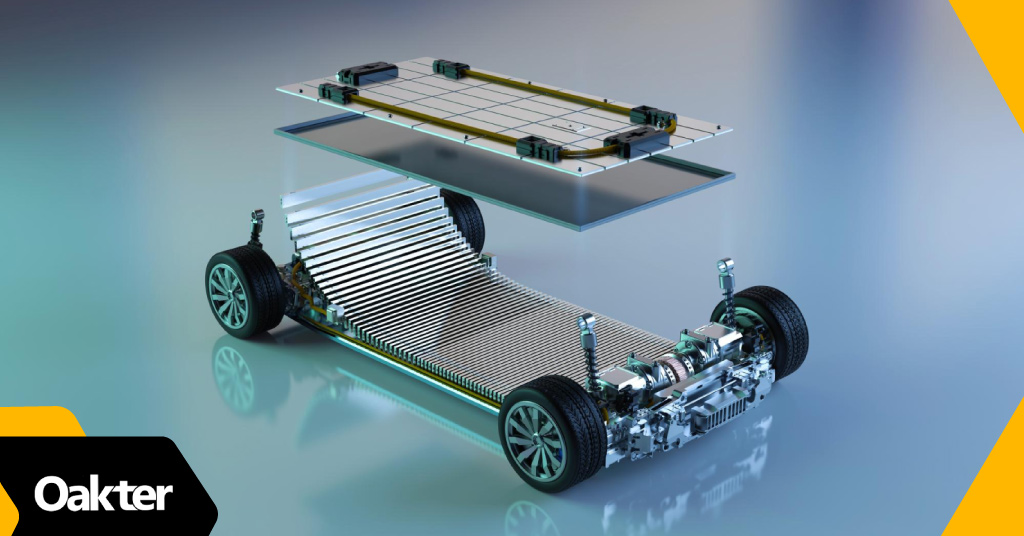

Unlike traditional lithium-ion batteries, solid-state batteries use solid electrodes and solid electrolytes rather than liquid or gel electrolytes. This solid construction makes them more structurally stable.

Several companies are developing prototypes using materials like ceramics or polymers for enhanced conductivity and safety.

Traditional Lithium-Ion Batteries vs. Solid-State Batteries

Lithium-ion batteries have made EVs possible by storing and delivering energy through the movement of lithium ions between positive and negative electrodes. The liquid electrolyte solution allows this ion transfer but comes with risks. Overheating can make the flammable electrolytes combust, requiring multiple safeguard systems.

Solid-state batteries utilise solid electrolytes rather than liquids to enable ion transfer. This removes the fire and overheating risks while allowing the battery to operate at increased voltages for more power.

The solid material also physically separates the positive and negative electrodes, preventing dendrites from forming through the electrolyte, which can lead to short circuits.

Additionally, solid electrolytes enable the use of lithium metal anodes, which can store more energy in a smaller space.

What are the Advantages of Solid-State Batteries?

Solid-state batteries boast a multitude of advantages, including:

1. Higher Energy Density

By utilising solid electrolytes, more battery cell volume can store active materials. This results in increased range – a key factor limiting EV adoption. Early prototypes boast 40% more capacity than standard lithium-ion cells.

2. Longer Lifespan

Without liquid components, solid-state batteries avoid common degradation issues. Companies claim lifecycles reaching 30+ years – drastically longer than the average EV battery today.

3. Faster Charging

The solid construction also permits faster charging – a limitation of existing EV plug-in technology. Some prototypes can charge to over 80% capacity in 10-15 minutes. This could revolutionise charging infrastructure down the line.

4. Safety Improvements

With no flammable liquids, solid-state batteries reduce the risks of fires or explosions. This makes them ideal for vehicle integration and charging stations. The enhanced safety provides peace of mind to manufacturers and consumers alike.

Challenges in Developing Solid-State Batteries

While promising, commercially viable solid-state batteries are still on the horizon. Significant research is required to improve performance and manufacturability at scale.

Key hurdles include:

- Finding optimal solid electrolyte materials that provide sufficient ion conductivity while remaining stable over thousands of cycles.

- Ensuring strong interfaces between the solid electrolytes and electrodes to prevent delamination or cracking that disrupts ion transfer.

- Designing cost-effective large-scale manufacturing techniques for producing precision, multi-layer solid-state cells.

Overcoming these challenges requires extensive testing, innovative chemical engineering, and strategic partnerships across the battery supply chain. For EV charging manufacturing companies, the companies best positioned to drive this transformation will shape the future of the industry.

The Significance of Solid-State Batteries for EV Charging Manufacturing Companies

For companies investing in charging infrastructure, solid-state batteries provide an opportunity to transform user experiences and enable superior vehicle performance.

1. Charging Speeds and Range

With faster charge rates and increased capacity, electric vehicles can charge faster and drive further between plug-ins. This will reduce range anxiety and require fewer public charging ports to power the growing EV ecosystem.

2. Performance

By storing more energy without increasing battery weight, solid-state technology can improve acceleration and responsiveness. This leads to a more dynamic and desirable driving experience – inspiring greater EV adoption.

3. Competitive Landscape

The pursuit of better battery technology has motivated various market actors to explore the field of SSBs, demonstrating a mix of rivalry and creativity.

Some of the leading companies in this area are: Toyota, Bosch, Ilika plc, Cymbet Corporation, Contemporary Amperex Technology Co., Limited, Toyota Motor Corporation, BYD, Gotion Inc., Svolt Energy Technology Co., Ltd., Samsung SDI and Apple, are investing heavily in prototyping to bring solid-state batteries to market:

Solid Power specialises in sulphide-based cells touting higher conductivity and capacity. They recently partnered with BMW and Ford with plans to begin producing in 2026.

Solid-state battery from QuantumScape achieved more than 1,000 charging cycles with still more than 95% capacity. Depending on the model, an electric car could drive more than 500,000 kilometres without any noticeable loss of range.

Billions in investments reflect automakers’ confidence in the technology. While timelines vary, most experts predict mass production over the next decade. These partnerships also indicate symbiotic relationships between battery innovators and prominent EV manufacturers.

The Economic and Environmental Implications

Transitioning to solid-state holds financial and ecological incentives by transforming electric mobility:

1. Cost Savings

Greater energy storage drives costs down per kWh. Improved lifecycles also minimise replacement rates. This benefits manufacturers investing in new infrastructure.

2. Sustainability

Increased adoption from reduced “range anxiety” means lower global emissions. Less waste also results from exceptional battery lifespan. These resonate with eco-conscious automotive brands.

Through strategic positioning, EV charging brands can leverage these value drivers to reinforce their market leadership early on while contributing to worldwide decarbonisation efforts.

What are the Future Implications and Industry Forecasts?

Most experts predict solid-state batteries will reach commercial viability later this decade, with adoption accelerating through 2030.

The market is expected to grow from just $85 million in 2023 to over $960 million by 2030 – a 41.5% compound annual growth rate.

Leading this revolution could significantly reshape the automotive sector. As range and charging rates eclipse gas vehicles, EV adoption is likely to thrive.

Solid-State Batteries: Powering the Future of EV Charging Manufacturing

Solid-state battery technology marks a new era for electric vehicles. While still facing developmental hurdles, early prototypes foreshadow immense improvements to capacity, charging rates, safety, and costs.

As the next-generation battery solution, solid-state holds transformative potential for EV charging infrastructure and the broader automotive space. Manufacturers are strategically poised to capitalise on these advances once commercialised.

With intense competition among battery startups and automakers alike, consumers and businesses worldwide eagerly anticipate the EV experience of the future.

Join Oakter in shaping this transformative journey. Choose us for pioneering innovation and ongoing advancements in solid-state battery development.

Contact us today to be part of the evolution towards efficient and eco-friendly electric mobility.

- https://slotjitu.com/

- https://linkslotjitu.com/

- jual303

- jual 303

- slot

- https://heylink.me/jual303/

- https://www.slotjitu.id/

- https://slot-gacor.id

- https://slot-gacor-2026.com

- https://adslotgacor.com/

- https://slotgacor77.id/

- https://slotjitu.net/

- https://bento.me/kawasan303/

- https://www.slotdepo10k.id/

- https://www.slotraffiahmad77.com/

- https://togelsgp2023.com/

- https://www.slotraffiahmad88.com/

- https://www.slotraffiahmad.net/

- https://www.slotraffiahmad.org/

- https://slotgacor-maxwin.com/

- https://www.nausenaadventures.com/

- https://www.kawasan303.org/

- https://slotscatterhitamgacor.com/

- https://superscatterhitam.com/

- https://www.slotraffiahmad.id/

- https://suleslotgacor.com/

- https://www.kawasan303.com/

- https://pgslottop.id/

- https://kawasan138.com/

- https://slotsuleofficial.com/

- https://slot-raffi-ahmad.com/

- https://scatterhitamgacor.com/

- https://linkslotgacor.id/

- https://sundulbola.com/

- https://ucosigtau.com/

- https://www.ia-itb.com/